|

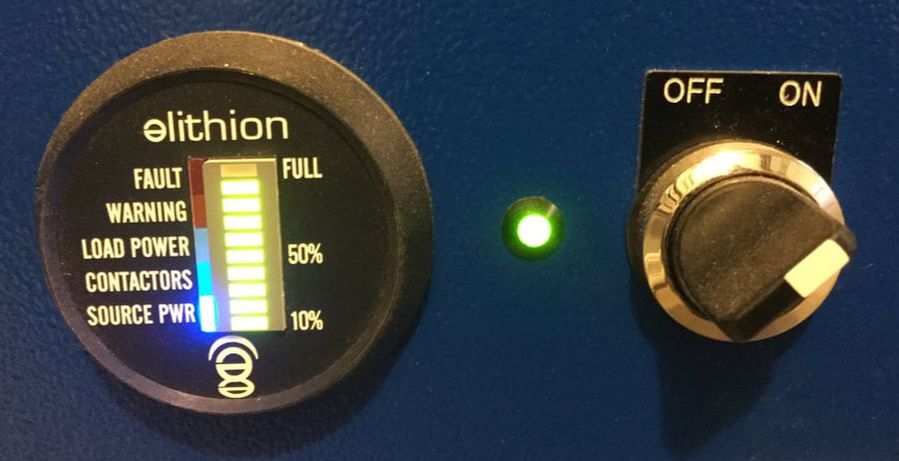

Lithium Iron Phosphate (LiFePO4) batteries have been a hot topic these days, with good reason. They are claimed by some to be “the future” in energy storage. Some advantages over the more popular Lead Acid (LA) batteries include longer life, greater discharge rate (up to 80% Depth of Discharge claimed as well), and little to no maintenance. A customer, now a friend of ours, who enjoys testing the latest technology, decided to give Iron Edison’s LiFePO4 Battery a try. We helped with the transition of his previous 48 Volt Lead Acid battery bank (that we installed in 2012), which consisted of sixteen Trojan L-16 RE Bs (740 Amp Hour total), to his current 48 Volt 360 Amp Hour LiFePO4. Normally, with Iron Edison, the Lithium batteries are housed in one large metal enclosure. However, as there were sizing restraints (concerning the entrance of the underground structure where the Balance of Systems is contained), Iron Edison configured the battery system in two separate smaller enclosures. These were easily paralleled together with the provided Anderson quick connect cables to complete the 48 volt system. Iron Edison boasts of their batteries being fully compatible with leading industry equipment, such as Schneider Electric, SMA, Magnum, and MidNite Solar. Our customer was already equipped with a Magnum MSPAE4448 Inverter/Charger and a MidNite Solar Classic 200 Solar Charge Controller. Once the battery set (S/N 011) was installed, it took some time working with the manufacturer to "dial in" the Classic 200's set pionts to completely charge the battery bank from 50% State of Charge (SOC) to 100% SOC in one sunny day. As of today, the change in the "end amp" set point seems to have mitigated the issue.

It’s only been three months since the batteries have been commissioned, but we’ve put together a preliminary list of pros and cons that we have observed during this period. There are some things we cannot comment on, for example long life and increased life discharge cycles, but we’ll continue to update the list if anything of importance arises. Pros:

Cons:

We still have much to learn, test and discuss about Lithium Iron Phosphate batteries in Renewable Energy applications. Have any experience with using Lithium Iron in the Solar Electric world you’d like to share? Please comment below. We’d love to hear your feedback!

0 Comments

This week we got a call from a customer who had a 17.5 kW Jacobs Wind Turbine (Jake) that was free spinning. We estimate that the blades were spinning approximately 50 rpms/minute…pretty fast. A coupling on the turbine’s drive shaft had broken before (above) the breaking mechanism (an unfortunate design flaw), so engaging the brake was not an option. It was necessary to climb the 100’ free standing tower and approach the blades from the backside, near the tail boom. The tail was secured and positioned so that the turbine was out of the wind, slowing the blades down. This made it easier to slip a 3/8”, 6’ long Galvanized Aircraft Cable (GAC), which had been fed through an old hose to protect the blades from any damage, around the nacelle and over one of the blades. The GAC was tightly secured with saddle clamps to ensure it remains arrested until a new coupling can be replaced, (or the customer updates to a Bergey 10 kW!).

Array Tech is a top global manufacturer of solar trackers. A Dual Axis Tracker follows the sun continuously, ensuring your array is always in optimum position. This can increase your power production by up to 40 % over a fixed array.

We have installed many DuraTrack DA Dual Axis Trackers and have found them to be very robust, even with the harsh environment and heavy winds we see here in Northwest Nebraska. Very minimal maintenance is needed, including lubricating the drive once a year and removing dirt or snow when needed. On a very rare occasion, it was necessary for us to replace the motor for a customer's tracker. Installing a new motor on a solar tracker might seem a little daunting, but it’s really quite an easy task if you follow the steps below. Instructions will come with your new replacement motor, however, we added a few steps and more pictures, to hopefully make replacement that much easier. Magnum Energy, a leading manufacturer of inverter/chargers for mobile and renewable energy applications, builds some of the industry's most reliable, efficient, and cost effective inverter/chargers on the market today. Specifically, the MS4448PAE 4000 Watt, 48 Volt inverter is our favorite for any off-grid system. Why? With a descent price, excellent and reliable design, and ease of use, it’s simply a great choice for an off-grid system. PriceThe retail price of the MS4448PAE will run around 2,100.00. While this isn’t cheap, we feel this is the best bang for your buck for a reliable, 4000 Watt, 48 Volt quality inverter/charger. It will be, after all, the heart of your system.

We were camping in the beautiful hills of Eastern Kentucky (EKY) this past summer when we started assembling a small "plug and play solar system" we could easily transport on our travels.

On one of his missions, Marc had developed a 12 Volt system that ran lights for a small hospital in North Sudan (MidNite Solar donated part of the equipment but this is another story). This got him interested in smaller, robust, off-grid systems that anyone could easily use. There are many small RV type plug and play systems available today, but some are either too small to produce the needed power, or they are very high priced for what you get. We wanted a system that we could trust and rely on as well as produce the power needed. We also wanted the final product to be an affordable power producing appliance that was in reach financially to a bigger group of the world’s population. |

|